The Norwegian company Stadt Power Technology (Stadt) sees huge potential for geared[ds_preview] electric propulsion in the maritime industry. Ships have been using gearboxes as part of their propulsion systems for many decades. Also the most noise-sensitive modern submarines use the gearbox to drive their propeller.

The fifth generation of drive technology – Stadt’s No-Loss drives – stands out as an ultimate solution when it comes to sustainability; including high efficiency, reliability, safety and stealth features the company stated.

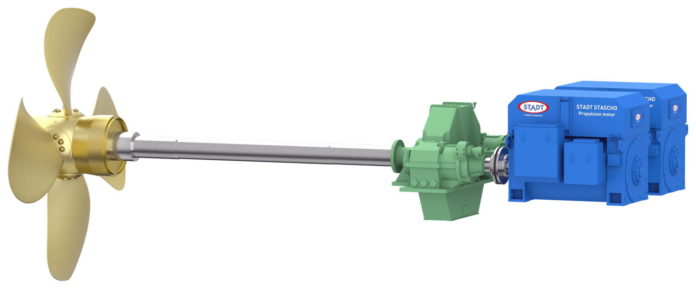

In general, a simple gearbox is a reliable and efficient device. The power losses count to somewhere between 1% and 2%, depending on the gear ratio, teething, bearings and lubricant Stadt informs. In addition a gear box can also give operational advantages such as increased redundancy, by using several electric motors in to one gearbox. In Stadt’s No-Loss electric propulsion drive systems, the use of the gearbox is also combined with the use of controllable pitch propellers.

Reasons why all these applications are using the gearbox are an increased torque and power and space and weight savings.

Field experiments over several years combined with simulations have shown that the Stadt’s No-Loss drive technology, will gain 5 to 6% in fuel savings per year compared to traditional AC drive solutions based on Non-sinusoidal drives. These savings add up with the general savings gained for the electric propulsion arrangement, where typically four to six generators provides the energy, and enable to shut off completely the power sources that are not needed any time. This leads to a fuel saving that may count up to 30% per year compared to ships with mechanical propulsion, Stadt says, in particular for ships with a variable load profile, DP, or doing slow steaming as part of their operation.