The past twelve months have seen only few changes to the portfolio of pod drive manufacturers. Solutions to be employed in ice become more important. HANSA shows products available on the market

Pod propulsors are the driving force behind latest cruiseships Operators explore new opportunities with help of azimuth thruster technology. This[ds_preview] kind of propulsion has swept the cruiseship industry in recent years and is becoming a feature of vessels being built for polar voyages.

Nowadays regions with more or less ice formation are increasingly catching the attention of owners in the course of this calculation. This is because polar regions may hold less ice in the coming years offering real prospects in efficient voyage planning.

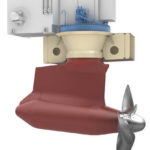

Not only the vessels’ hull structure but also the propulsion are subject to special requirements. Rolls-Royce has the so-called Mermaid ice-strengthened pods in their portfolio. These drive systems are specifically designed for all vessels operating in toughest Arctic conditions. Mermaid ICE units are designed to IACS PC4 and provide excellent hydrodynamic performance for open sea voyages for fuel savings in a mixed operational profile, the company says. The new HICE pods for heavy duty ice applications are designed for ice classes to IACS PC1. According to the manufacturer both types are equipped with robust heavy duty induction Pulse Width Modulation (PWM) engines with high torque at low rpm suitable for tough ice milling conditions.

ABB also offers a range of products suitable for sailing under ice conditions. At the end of August 2017 the LNG carrier »Christophe de Margerie«, owned by Russian operator Sofcomflot, was the world’s first vessel to cross the Northern Sea Route without the aid of an ice-breaker. The carrier is powered by ABB’s Azipod electric propulsion technology. The 172.600 m3 Arctic LNG tanker which features a lightweight steel reinforced hull is the largest commercial ship to receive Arc7 certification. The tanker is capable of travelling through 2.1m thick ice, ABB reports and crossed the Northern Sea Route (NSR) from Hammerfest, Norway to South Korea in 19 days instead of the 30 days required to travel the regular southern route through the Suez Canal. This record time resulted in less fuel consumption and ship fuel emissions, the company says.

All of the 15 vessels constructed for the Yamal LNG project were equipped with three Azipods each. According to ABB they provide a high degree of maneuverability, and enable the use of the stern-first motion (Double Acting Tanker, DAT function) principle which is necessary to overcome hummocks and heavy ice fields.

Furthermore, ABB added a new product to its portfolio. The Azipod DO is the latest member of the Azipod family for the power range from 1,6 to 7 MW. Azipod DO should provide cost efficient, reliable and energy saving operations for merchant, offshore and special vessels. The high performance of the thruster is achieved by a unique dual cooling of the propulsion motor that combines a direct cooling to the surrounding sea and a separate air cooling. According to ABB the pod represents a cost efficient and reliable solution for DP vessels and other ships requiring high thrust. The latest order for the Azipod DO was placed for a new Lindblad Expeditions Holdings vessel that will take passengers on exploration cruises to remote polar areas. The newbuilding will be constructed by Ulstein Verft and receives two Azipod DO propulsion units. The vessel delivery is expected for the first quarter of 2020.

No claim to be exhaustive, all information without guarantee