Offering engineering services via the web is a way to »democratize« design tasks and work flows. The Computer Aided Engineering system CAESES has been extended to support web-based applications (webApps)

Cloud computing, Software-as-a-Service (SaaS) and web-based applications are changing the way designers and simulation engineers perceive[ds_preview] their working environment. While many engineering tasks may still be done most efficiently on local hardware, other jobs can be more economically realized outside the office. Smaller technical applications or »Apps« may offer very specific functionality dedicated to a certain task.

The so-called Wageningen webApp has been developed for the design and geometric modeling of propellers. It builds on CAESES as a flexible Computer Aided Engineering system that allows wrapping selected sub-sets of functionality and offering it via a web-browser from any device for intuitive, albeit inherently limited, work flows. The expertise of an experienced propeller designer has been combined with data from the Wageningen B-series. This propeller series is most popular due to its wide range of parameters and the availability of polynomials that represent propeller performance. The idea is to generate added value for the app user quickly and conveniently without claiming an all-encompassing functionality.

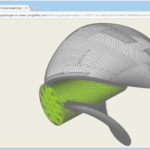

Building on CAESES’ parametric modeling techniques a propeller is generated with just a handful of inputs. The webApp then offers a watertight geometric model and determines the propeller’s efficiency. In the final step, the geometry can be downloaded, for instance as an stl-file to be used as a stock-propeller for a numerical propulsion test or for rapid prototyping via 3D-printing.

Design task

The example of a propeller for a fast power boat illustrates the underlying CAESES technology of modeling and »appification«. The task: A new propeller shall be developed for a small power boat, similar to the classic Riva Junior from 1966.

The Wageningen B-series data can be used to determine optimum diameter and number of blades along with mean pitch, blade area, and the corresponding open water curves. These particulars determine all other blade details, like skew-back, rake, radial pitch distribution, blade contour, and blade section shapes.

This would already yield the final B-series design. However, a few modifications appear to be beneficial and have been made available within the webApp: Firstly, it is advisable to check the blade strength. Secondly, thinking about small adaptations, it appears easy and without too much risk to vary the blade rake. The original B-series propellers feature rather pronounced backward rake, which not always fits the purpose. Finally, the B-series propeller hub might not be suitable. In order to generate a proper hub, the webApp determines the required diameter for the specified engine output and shaft rpm and selects the corresponding hub dimensions according to ISO4566.

Modeling within CAESES

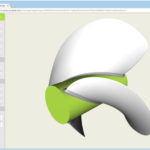

The design process of the B-series propeller in CAESES is divided into three parts: profile definition along with the blade creation, hub modeling and the merging process to create the final and watertight propeller geometry.

In the very first step, 2D profiles are defined by using either mathematical formulas or any other curve type that is available within CAESES, such as spline curves. The 2D profile generation is parametric and, once defined, always follows the user input such as changes of the diameter or the thickness distribution.

For the B-series, a number of discrete sections are created as 2D curves and transformed into the 3D space as cylindrical sections, based on the specific radii taken from the literature. The 3D sections are subsequently skinned by a NURBS surface, creating a mathematically closed definition of the main blade. The main blade is subsequently closed by a dedicated surface feature within CAESES. The shaft is determined via ISO4566. In order to define the blade’s thickness distribution, an internal optimization is triggered based on the user inputs. These inputs are the actual power, the water density, rpm, gear ratio, propeller diameter, the vessel speed, the expanded area ratio, number of blades and the Reynolds number.

These input data are converted into target values for the torque (coefficient) and the advance ratio which have to be met by finding the corresponding pitch. As a result, the iterated pitch value and the calculated thrust (coefficient) value are known.

For the thrust found the blade root thickness is calculated via basic beam theory. It is computed using the thrust value, the material information, the pitch angle and the chord length at the root, the number of blades and the torque value. The tip thickness being fixed with a value of 0.5% of the propeller diameter, a linear thickness distribution between the hub and the tip is assumed. With this information, the 2D sections are completely defined and the 3D surface can be generated, as described above.

For creation of a solid geometry the blade surface is copied and rotated according to the number of blades. An intersection operation is then undertaken which results in a watertight solid body, taking into account a suitable fillet. Finally, the propeller’s weight and its volume are calculated from the solid geometry as additional information for the user.

»Appification«

The process of converting a CAESES project into a browser-based webApp is based on a set of XML-files. These files contain the information for the web-browser, defining the front-end layout and the inputs.

Basically, the user can define any CAESES command to be triggered when a button is clicked in the front-end. In the case of a download of either an stl- or a STEP-file, a CAESES export command is triggered remotely for the final propeller geometry object.

The XML files are simple to understand and can be created manually by using any ASCII text editor so that a high level of customization is possible. Alternatively, a user can directly save a project set-up by clicking on a button in the CAESES GUI. This automatically generates an XML file that is ready to be displayed as a webApp.

CAESES includes a web-server implementation which reads the corresponding XML files. The CAESES application and project files are packed as Docker images and uploaded to a private Docker registry. Multiple servers represent a Docker Swarm which load-balances the CAESES requests. A proxy server implementation distributes all CAESES sessions to the Docker Swarm. As soon as a webApp is started a user session is launched within which a CAESES instance is being run in batch-mode on a (remote) server. Each user session is encapsulated in a secure environment so as to ensure confidentiality. The communication between the end user’s web-browser, e.g. Firefox, Chrome, and the CAESES container instance uses AJAX, called to exchange values and other data such as geometry. The browser front-end is fully responsive and handles requests from various devices such as mobile phones, tablets and workstations.

Perspectives of webApps

In general, there are different types of users and providers that can benefit from the appification of tools. The target groups of the Wageningen webApp are:

• CFD specialists that need a high-resolution stock propeller for self-propulsion analysis,

• Naval architects that know the input data for their design (diameter, revolutions per minute etc.) but do not have the background knowledge for generating the geometry,

• Quick double-check and/or estimate for the expert,

• People that want to replace a propeller that was damaged and for which dimensions are known (naturally, the propeller to be replaced must be sufficiently close to a B-series design),

• Hobbyists that would like to have a reasonable propeller for their project (water-bikes, foils etc.) and that would not have the financial means to engage an expert,

• Students that would like to get an appreciation of propeller geometry and design.

A wider group of beneficiaries are consultants that have expert knowledge and/or tools for specific applications for which they see a certain market that is, however, difficult to access. These people and/or organizations can utilize the CAESES appification environment to complement their approach of marketing and dissemination.

Stefan Harries